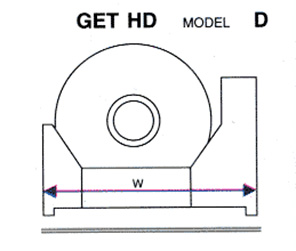

Vaccum Tumbler GET HD Model D

For Bone-in & Bonless Meat, Poultry, Fish, Sea Food

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

- VACUUM TUMBLER GET HD MODEL D (2b)

Process Description

| CONVENTIONAL METHOD | GET METHOD | |

| DEBONIONG and/or TRIMMING |

DEBONING and/or TRIMMING |

| INJECTION | INJECTION |

| CURING | CURING |

| COOKING or SMOKING | TUMBLING |

| CHILLING | * COOKING or SMOKING |

| PACKAGING | CHILLING |

| PACKAGING |

* For thermal processed meats only.

** All sizes available (to meet customer’s space, process speed, or other requirements).

*** Hydraulic options available on HD models.

Technical Features

– Variable speed drive, mechanical & hydraulic option.

– Control panel – manual and automatic continuous or programmed action.

– Built in vacuum pump.

– USDA approved.

– Easy to operate, maintain and sanitize.

– Heavy duty contruction.

– Safety control.

– Optional:

Loading By vacuum suction, bucket dumper or conveyor.

Meat Temperature control option available on glycol- jacketted models.

Increase Profit !!

Our F.C.C. system assures higher yields, superior quality and longer shelf life.

FAST

COLD

CLEAN

Weight and Dimensions of GET HD Tumblers

| GET HD MODEL |

DIMENSIONS (in cmts.) | TOTAL VALUME Liters |

NETWEIGHTKgs. |

MEAT CAPACITY (in Kgs.) May vary with source or cut of meat | MEAT CAPACITY (in Lbs.) May vary with source or cut of meat | ||||

| LENGTH | WIDTH | HEIGHT | LOADING BY LIFT | LOADING BY SUCTION | LOADING BY LIFT | LOADING BY SUCTION | |||

| 1901 D | 226 | 264 | 229 | 6000 | 3200 | 2000 | 2500 | 4400 | 5500 |

| 2000 D | 189 | 280 | 241 | 4800 | 1950 | 1600 | 2000 | 3520 | 4400 |

| 2001 D | 234 | 280 | 241 | 6800 | 3550 | 2270 | 2890 | 4994 | 6358 |

| 2002 D | 264 | 290 | 254 | 8160 | 4000 | 2720 | 3400 | 5984 | 7480 |

| 2003 D | 290 | 290 | 254 | 9540 | 4500 | 3180 | 3970 | 6996 | 8734 |

| 2004 D | 381 | 290 | 241 | 13620 | 5000 | 4540 | 5680 | 9988 | 12496 |

| 2200 D | 346 | 310 | 272 | 15000 | 5350 | 5000 | 6250 | 11000 | 13750 |

| 2300 D | 355 | 330 | 285 | 16350 | 5550 | 5450 | 6820 | 11990 | 15004 |

OPTIONAL LOADING SYSTEMS

| LENGTH Cm. | WIDTH Cm. | HEIGHT Cm. | WEIGHT Kg. | MEAT CAPACITY | |

| LIFT BUCHET | 140 | 110 | 125 | 115 | 200 |

| SUCTION TRUCK | 200 | 100 | 97 | 135 | 1150 |

1 INCH = 2.54 CM.

1 LB. = 0.454 KG.

Advantages

- Product Stability.

- Increased yield upto 20-30%.

- Improved texture, appearance & uniformity of taste.

- Lower shrink during cooking cycle.

- Lower drip loss in frozen products.

- Shorter production cycle (curing time).

- Quick return on investment.

Rights and Changes

GAL-ESH Machines fulfill the valid regulations concerning CE throughout Europe.

The information above, represents our best judgment and is based upon our experience and work previously done.

The company assumes no liability whatsoever in connection with the information contained within.

The company reserves the right to make changes to the specifications.