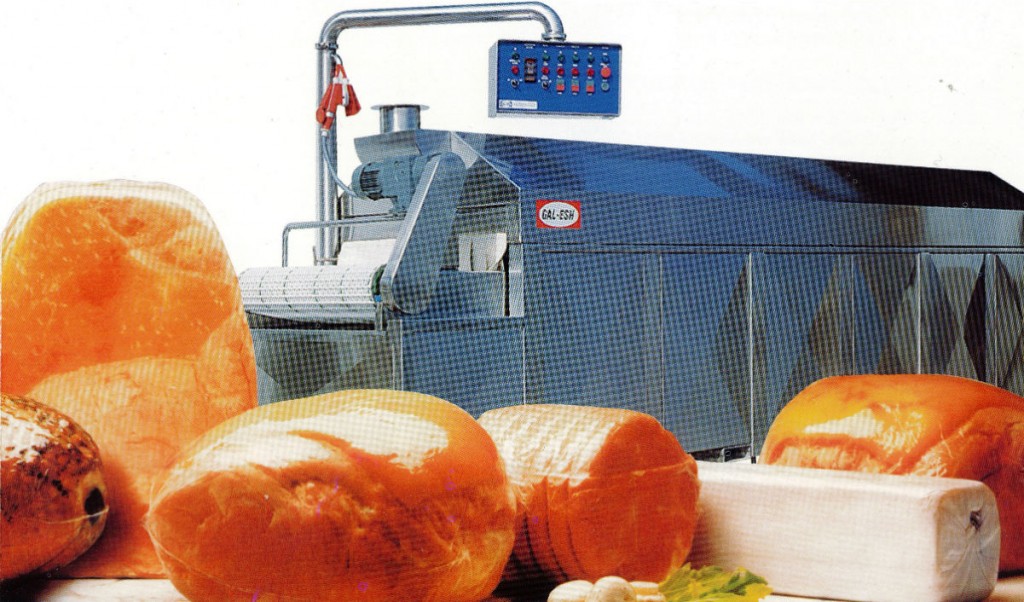

Pasteurization Tunnel For Deli Meat

For Vacuum Packed Meat

GAL-ESH System is designed to process cooked, smoked, and chilled vacuum packed Products.

Reducing bacterial contamination to improve product quality, increase stability, preserve freshness, and extend shelf life.

- PASTEURIZATION TUNNEL FOR DELI MEAT

- PASTEURIZATION TUNNEL FOR DELI MEAT

- PASTEURIZATION TUNNEL FOR DELI MEAT

- PASTEURIZATION TUNNEL FOR DELI MEAT

Gal Esh System

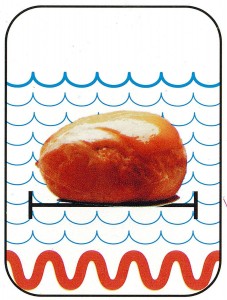

Hot Water Bath

Advantages: Simple Method

Disadvantages: Water temp. is not controlled and constant.

Pasteurization Credibility – Low!

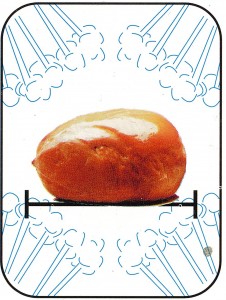

Steam Chamber

Advantages: Simple Method

Disadvantages: Steam has a poor Thermal Conductivity.

Pasteurization Credibility – Low!

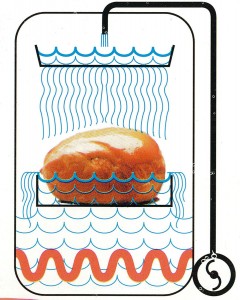

Circulating Water (Gal Esh System)

Advantages:

1. Short processing time (3 minutes) does not affect product characteristics.

2. Uniform surface heat distribution

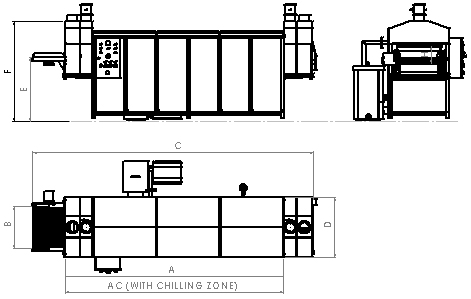

Technical Details

- A, AC, B,C,E,F AND H are avilable in al sizes (to meet customer space, Process speed, or other requirements).

- Pasteurization tunnel is avilable with or without a chilling zone.

Advantages

- Product Stability.

- Security in Processing.

- Preservation of Freshness.

- Extension of Shelf Life.

- Extended shelf life (stocks level control).

- Reduced product recall of spoiled products.

- Distribution better and cheaper.

- Compact construction (Saving Space).

- Easy operation and maintenance.

- Energy efficient.

- Reliable.

About The Product

Machine For Surface Pasteurization Of Vacuum Packed Processed Meat.

The system is designed to process cooked, smoked, and chilled vacuum packed

Products. Reducing bacterial contamination to improve product quality, increase

stability, preserve freshness, and extend shelf life.

In this new system the product packed in heat treatable vacuum bags passes a

surface pasteurization process of circulation water in short cycle of 3 minutes at 900 C (average values dependent upon the specific conditions). This treatment drastically reduces bacteriological contamination without altering product appearance and quality. This process ensures safety to producers and quality to customers.

GAL ESH tunnels can be combined with existing packaging lines. The water circulates around the product providing rapid heat exchange and uniform heat distribution.

GAL ESH tunnels unique construction, is protected under European and US patents.

This system performs better than other existing systems, where product is contaminated during the packaging, transportation and storage, contamination that can cause product deterioration, change of colour and taste, and reduces shelf life.

Rights and Changes

GAL-ESH Machines fulfill the valid regulations concerning CE throughout Europe.

The information above, represents our best judgment and is based upon our experience and work previously done.

The company assumes no liability whatsoever in connection with the information contained within.

The company reserves the right to make changes to the specifications.